making powders

of titanium, nickel, zirconium, iron, cobalt

and other alloys for additive technologies, surfacing and spraying

ADDITIVE TECHNOLOGIES.

RELEVANCE AND QUALITY CRITERIA

Additive technology (3D printing) – a technology where a three-dimensional object is created by applying successive layers of material (printing, growing) according to the digital model. A special device – a 3D printer, which provides the creation of a physical object by sequentially applying material based on a 3D model, performs printing. Each product needs its own adapted technology.

The quality and cost of products obtained by 3D printing technologies primarily depend on the main consumables – spherical metal powders.

When choosing additive equipment, preference is given to those manufacturers who allow the customer to choose the supplier of powder materials, including localized manufacturers and those who believe that the source of powders does not matter if the requirements for their parameters are met.

Based on the analysis of the 3D printer market, based on a comparison of technology, material, and field of printing, cost, performance, ability to build small fragments, construction accuracy, and others, we analyzed the raw material requirements of major European manufacturers from Germany and France.

In general, the parameters of powders can be classified into 5 categories:

- Chemical composition;

- Geometry;

- Mechanical and physical properties;

- Packing and transportation;

- Expiration date.

Based on these requirements, our company has developed quality criteria for its powders at the level of European standards.

LLC “MULTIFLEX” is a manufacturer of spherical metal powders from various alloys. The main activities include the manufacture of powders of titanium, nickel, zirconium, iron, cobalt, and other alloys for additive technologies, surfacing, and spraying.

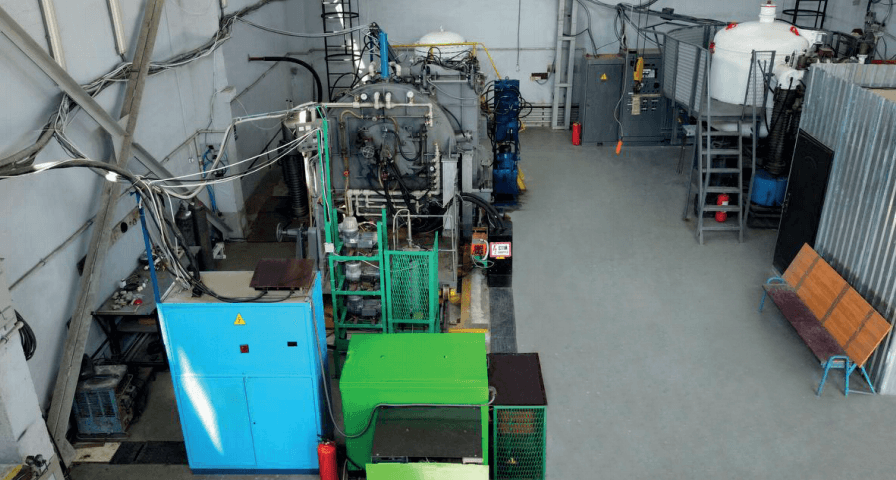

PRODUCTION CAPACITIES OF MULTIFLEX LLC

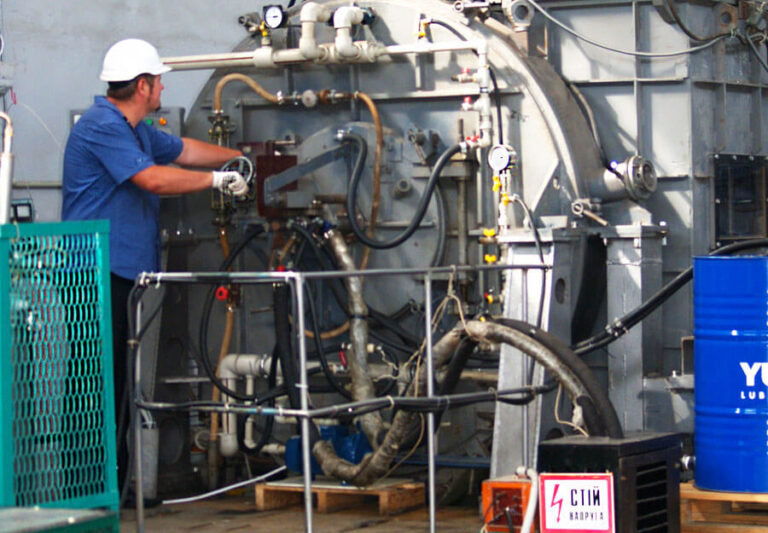

Centrifugal Spray Installation-4

DEEPLY MODERNIZED

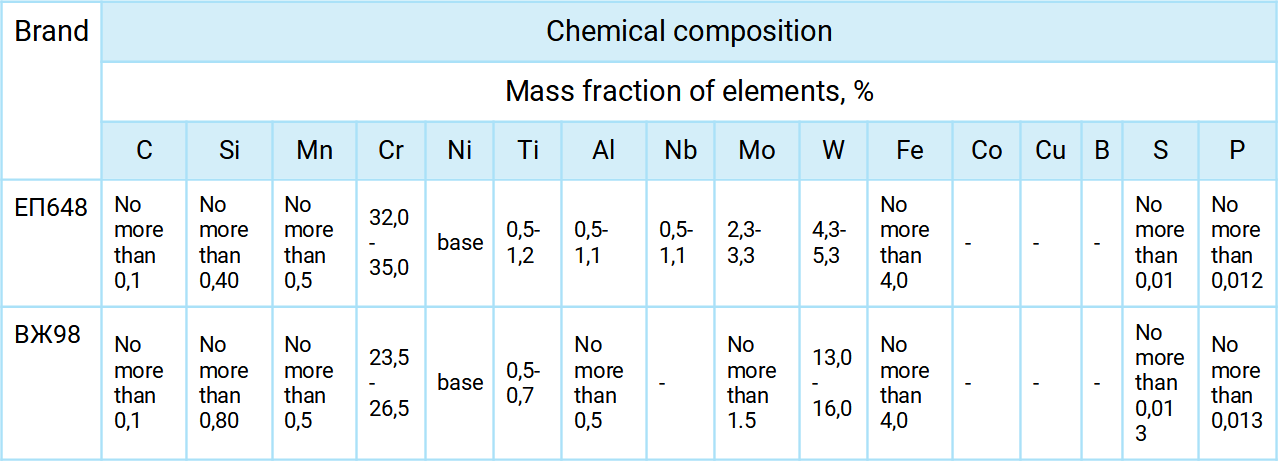

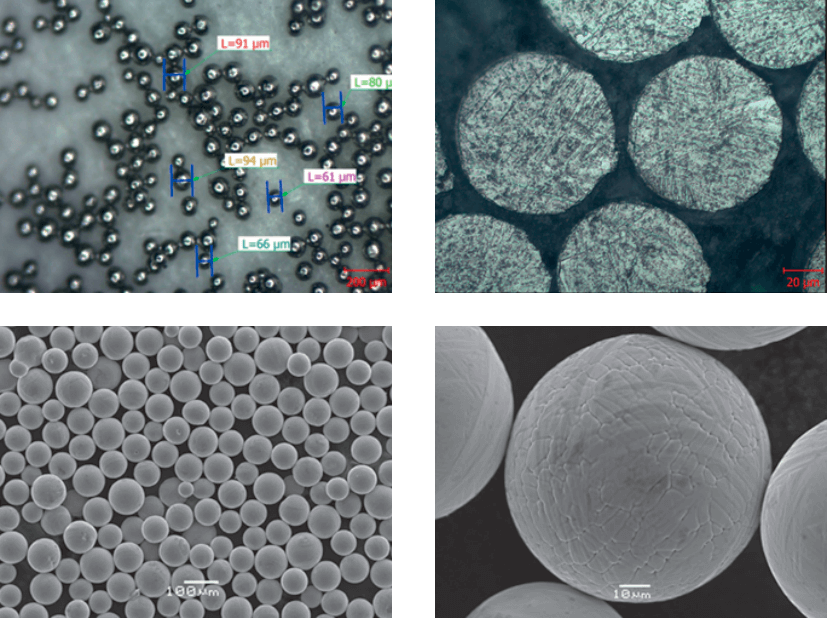

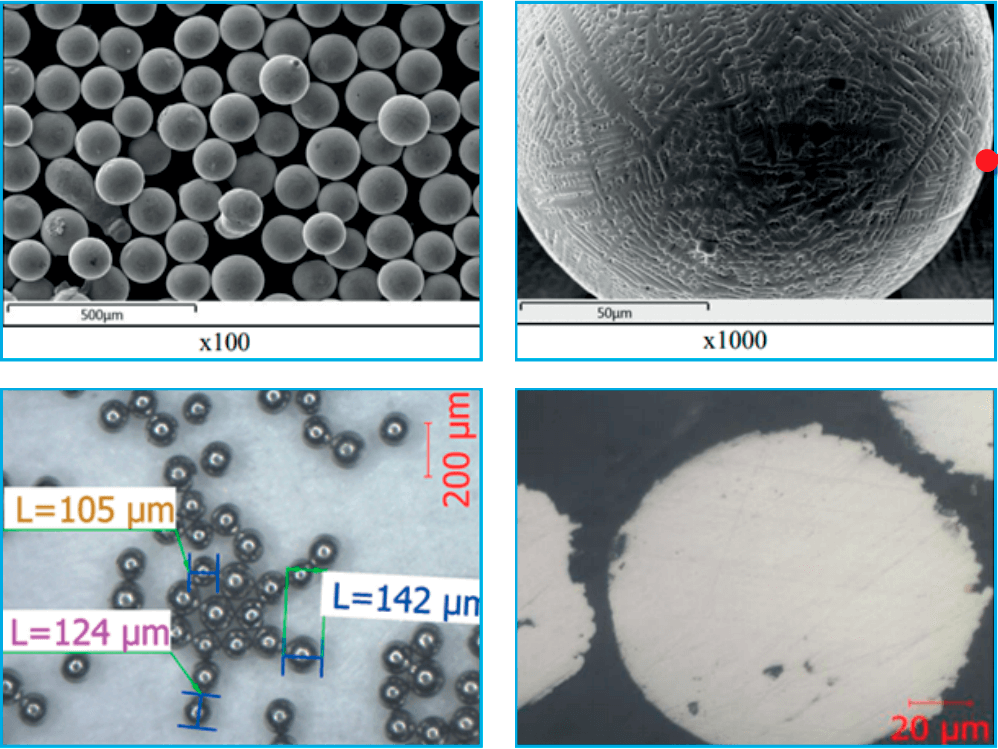

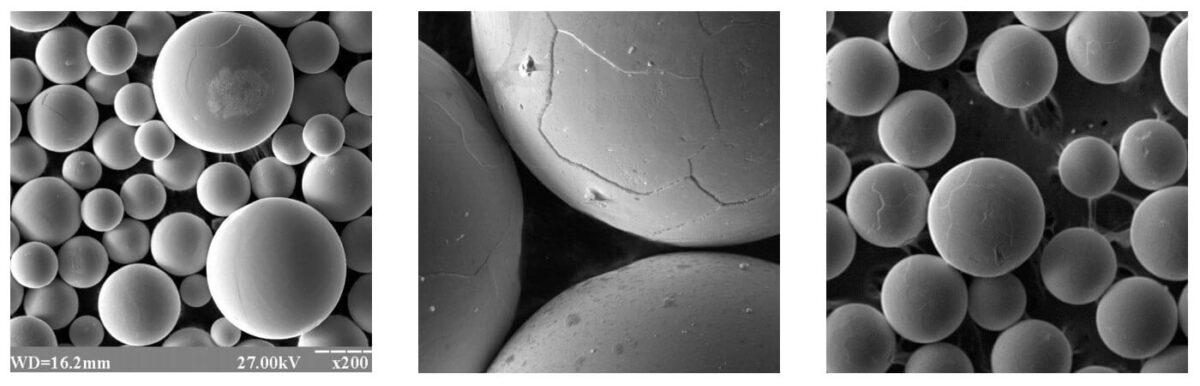

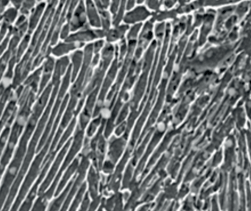

The unit is used to obtain spherical powders by melting technology and simultaneous spraying of a cylindrical workpiece with a stream of ionized inert gas – plasma, according to the international classification: Plasma Rotating Electrode Process (PREP).

Spraying product – spherical powders of particles with sizes from 10 μm to 200 μm.

We use rods Ø 50 mm, 700 mm long with simultaneous loading up to 50 pieces as preparation. It is possible to use both cast and deformed blanks.

We use a gas mixture as a substance for plasma formation.

It consists of high-purity gases: helium and argon.

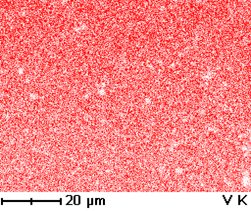

The use of pure gases in combination with high-performance vacuum equipment makes it possible to obtain powders with an oxygen content of up to 0.05% in titanium-based alloys and up to 0.005% oxygen in heat-resistant nickel-based alloys.

ADVANTAGES OF TECHNOLOGY:

- powders are of high quality and can be used in the aerospace industry, mechanical engineering, medicine.

- powders have a perfectly spherical shape, they do not have satellites and internal pores, which are characteristic of powders obtained by gas atomization.

This technology makes it possible to guarantee the chemical, particle size distribution, and shape of powders.

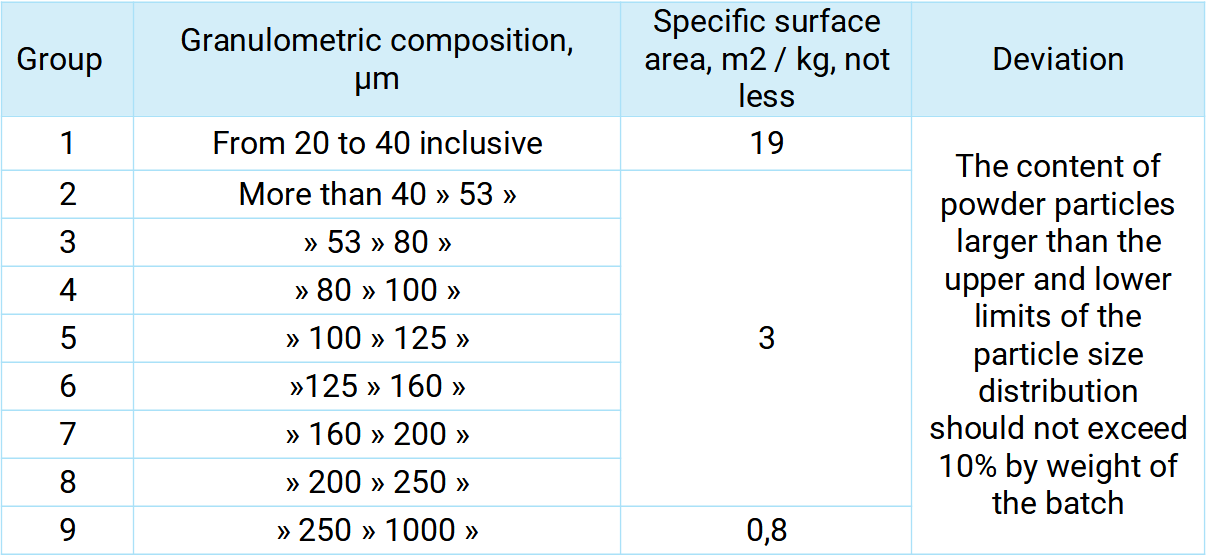

For the differentiation of the finished powder, a multifunctional sieve is used, which has high productivity and provides sifting of powders by particle size of 20 μm and more.

VACUUM OVEN

Designed for heat treatment of surfactants and their alloys in vacuum or shielding gases.

The main operations in a vacuum furnace: annealing in vacuum or shielding gas, vacuum aging, high-temperature isothermal sintering of powder metallurgy products, diffusion soldering, thermal preparation of powders of various shapes, and compositions.

POWDER MATERIALS MANUFACTURED BY MULTIFLEX LLC

Spherical powders are raw materials for additive technologies, surfacing, and spraying of products. The complex technical methods used in production allow getting any powder compositions and control their purity. The nomenclature of powder is various: from powders of structural steel to powders of titanium of high purity.

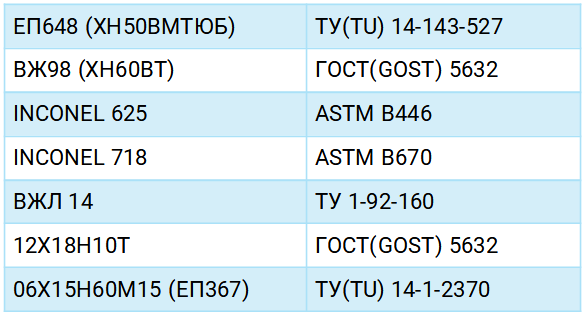

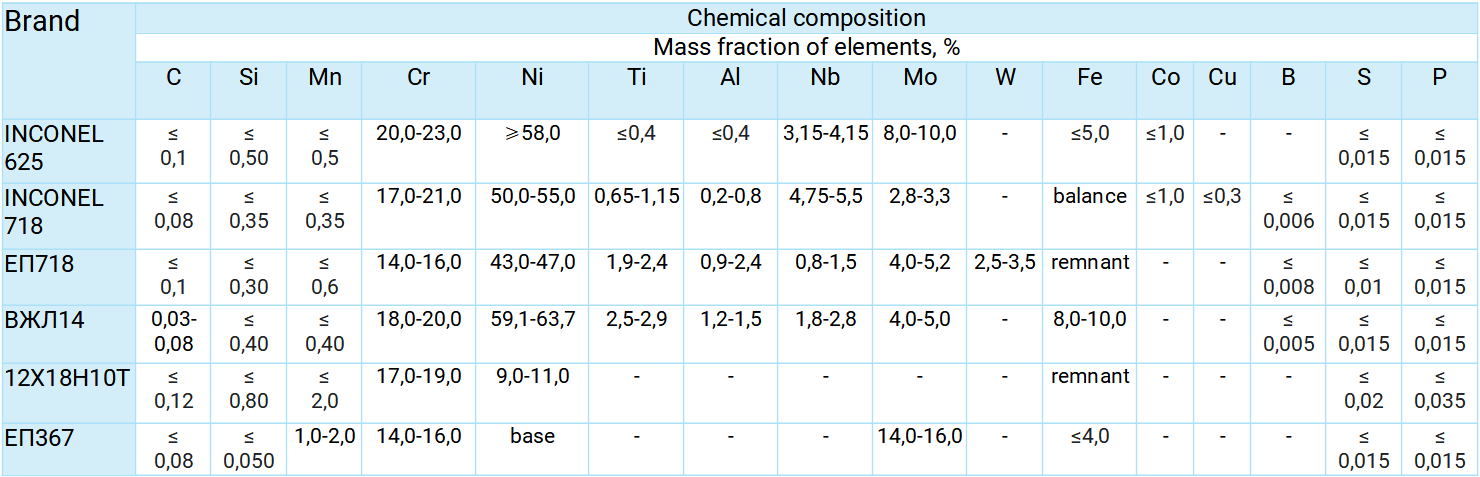

Powders from heat-resistant steels on the basis of nickel, which are already mastered at our production:

CHEMICAL COMPOSITION OF POWDERS OBTAINED FROM NICKEL-BASED ALLOYS

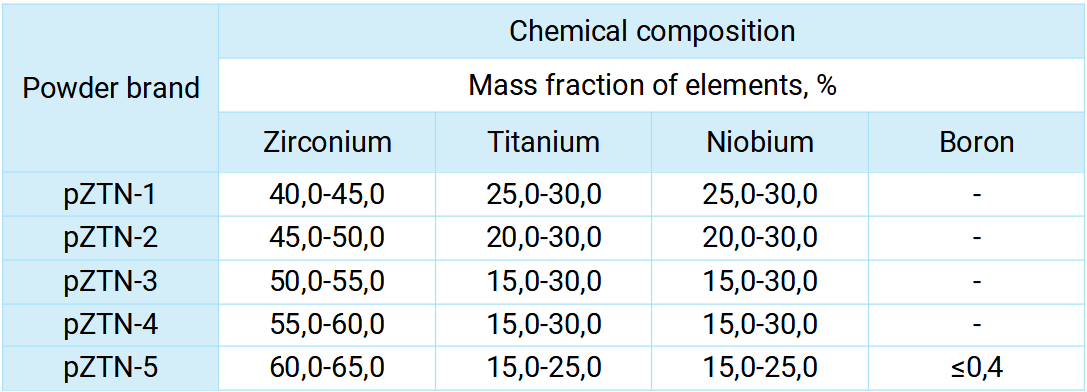

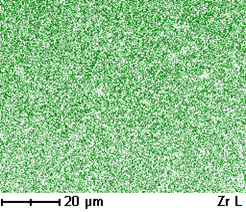

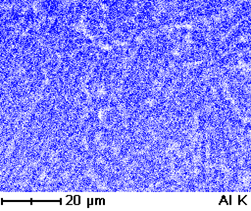

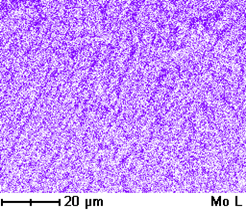

ALLOY POWDER BASED ON ZIRCONIUM-TITANIUM-NIOBIUM SYSTEM

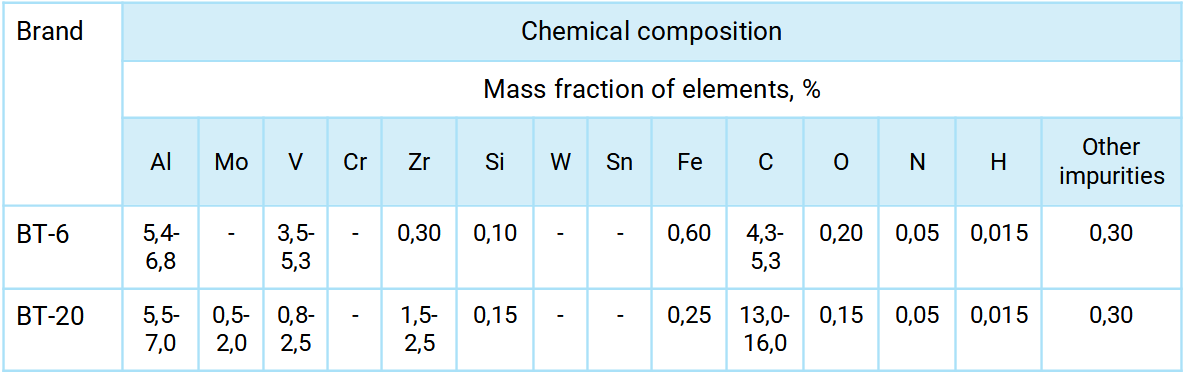

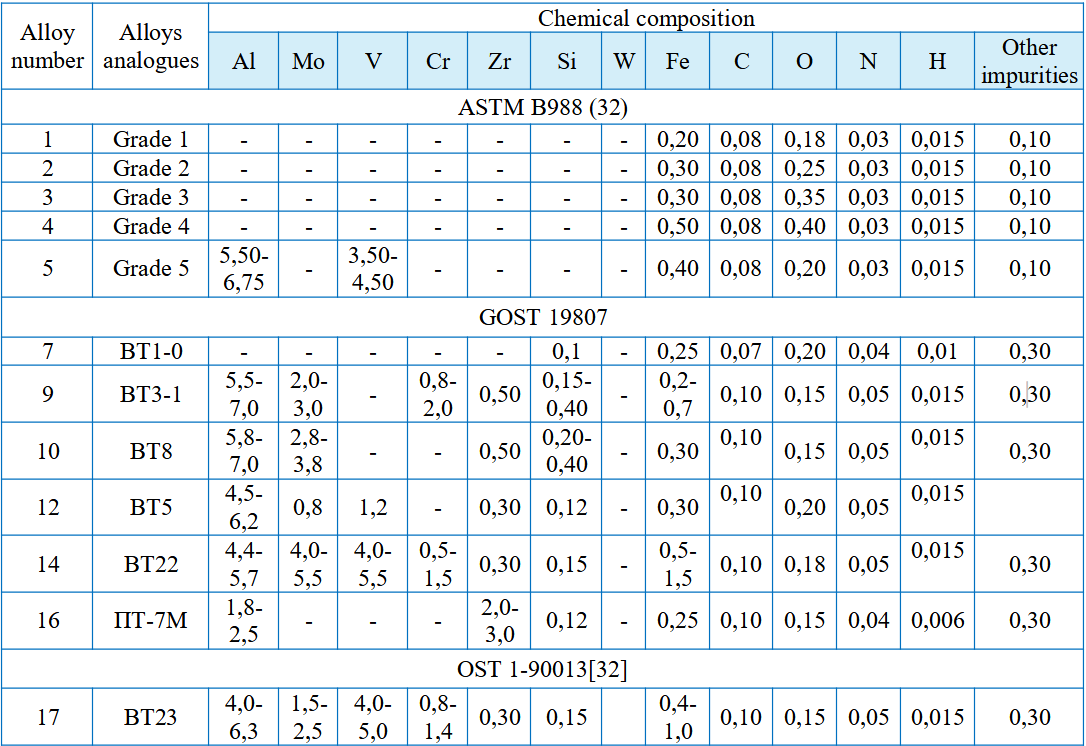

CHEMICAL COMPOSITION OF POWDERS OBTAINED FROM TITANIUM-BASED ALLOYS

Note 1.

The mass fraction of elements is maximum, if no boundaries are given. Other impurity content is allowed at the customer’s request. (For example, Grade 5 with an oxygen content of not more than 0.15%; nitrogen – 0.040%; hydrogen – 0.012%; iron – 0.25%.)

Note 2.

For powders of titanium alloys according to GOST 19807 and OST 1-90013 with a particle size less than 100 μm, an increase in oxygen content up to 0.20% is allowed.

PARTNERS

and good friends